2023-10-30

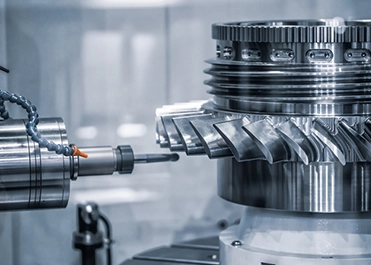

Titanium alloys are a variety of alloy metals made of titanium and other metals, which are relatively scarce and expensive; titanium alloys are characterized by high strength, light weight, corrosion resistance and high temperature resistance, and can be used in a variety of fine chemicals, which are mainly used in the automotive industry, aerospace, nuclear industry, chemical and petrochemical industries, dentistry and medical restoration and other fields.